If you are looking for a reliable replacement engine for your Jaguar XJ X350 or X358 and finding it to be an uphill task then you are not alone. Due to its limited production numbers and its classic status, the engines are in high demand and it’s not easy to find a working engine at a good price. However, Royal Rebuilds is your ultimate helping hand as we stock a large amount of used and reconditioned Jaguar engines that include all variants and models. We ensure that we offer excellent quality engines at market competitive prices and pair the valuable repair and fitting services so you can get the whole task completed under one roof.

Classy and Advanced XJ (3rd Gen)

Jaguar started the production of the Jaguar XJ in 1968 and it went from strength to strength since then. After many variations through the years, XJ 3rd generation was launched in 2003. It was introduced during the Ford ownership era and the engineers at ford did complete justice to the classy and popular XJ. A brand-new aluminium platform was created that was 40 % lighter yet 50% stiffer and improved the handling. Advanced electrical systems were introduced and self-levelling adaptive air suspension was on hand to keep the ride smooth and seamless.

The exterior of the XJ 3rd generation was conservative yet stylish as it retained all the style elements such as twin front lights, slatted grille and reclining back. The interior extends the classic theme and you see a lot of wood veneer finish and plenty of space. The suspension was taken from different Ford models and provided a smooth and comfortable ride quality.

Smooth and Dynamic Engines of XJ X350 and X358

Being a sizeable saloon, XJ has always received the best and most robust engines to keep this vehicle ahead of its competition. Especially when the X350 was introduced at the beginning of the 3rd generation of XJ, it was given a comprehensive range of engines.

The range started with a 2.7-litre diesel engine that was capable of delivering 207 hp with 0-60 acceleration in under 8 seconds and a top speed of 222 km/h. Next comes the 3.0 litres V6 producing 238 hp, acceleration from a standstill to 60 mph in 7.7 seconds and a top speed reaching 233 km/l. A 3.5 litre V8 was capable of producing 258 hp which brought down the 0-60 acceleration to 7.2 seconds and increased the top speed to 242 km/l. then there were 4 variants of 4.2-litre displacement that produced 298, 300, and 400 hp. Those engines were the reason that this vehicle received such widespread acclamation.

In 2007, the XJ was given a major facelift. Not only it improved the aesthetics but also brought some brilliant and more efficient engines as well. The range started with the same displacement as its predecessor. A 2.7-litre diesel engine produces 207 hp. Then came a 3.0-litre V6 engine producing 238 hp and then a 3.5-litre V8 that produced 258 hp. Then came 2 variants of 4.2 litres V8s producing respectively 298 hp and 395 hp.

Those engines were quite good as far as the performance was concerned. However, reliability is not the strongest suit for those engines. This is why engine replacement is quite normal for those models of the XJ. You can buy a brand-new replacement engine from the local dealership but dealerships are notorious for being expensive. You can save some money if you look for some used or reconditioned engines. However, it’s not easy to find reliable used or reconditioned Jaguar XJ engines and you may have to find a trusted online source that keeps those engines in store and provide them at a market competitive price.

Your Reliable Source for Low Mileage XJ Engines

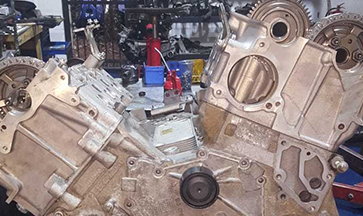

Royal Rebuilds has invested over two decades of experience and resources in providing the best quality low-mileage engines to its customers. Our teams of experts are dispatched to reliable engine sellers who inspect and purchase the used engines and bring these engines to our facility. We run several tests to ensure reliability and once we are satisfied with the results, we put these engines on sale.

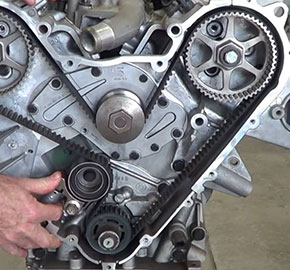

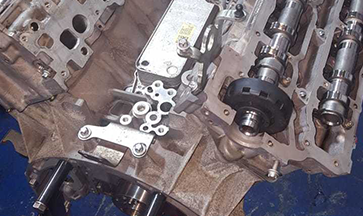

We choose some of the low mileage engines for reconditioning purposes. This involves stripping the engine to the block and assessing all the parts. Any defective part is replaced with a new genuine part and the engine is put back together expertly. Such is the quality of our reconditioning process that the engine that goes through this process is as good as a new engine in its durability and performance.

Save Valuable Cash and Gain Satisfaction with Us

We ensure that when you choose to buy a used or reconditioned Jaguar XJ engine from us, you get to save a significant amount of money. We estimate that we can provide you with savings of up to 60% compared to the price of a brand-new engine. there are further savings available on festive or seasonal sales.

No business can grow without offering satisfaction to its customers. We do this by providing a warranty with every engine that is sold by us. The warranty period could vary according to the condition and price of the engine.

We Deliver the Engine to You

Picking up the engine from our facility is not always a possibility for the customers. We understand this and can arrange a reliable and quick delivery of the engine to your specified destination at an economical cost. If you would like to get the engine fitted by us then we can arrange vehicle recovery for you. We bring the vehicle to our facility, fit the engine, test it thoroughly and bring it back to your doorstep all in a reasonably charged package. You can book an appointment online or over the phone and we would be happy to help.