The 3rd generation of Range Rover or MK3 or the LR 322 was the most game changing vehicle in its class. Its exterior designing was changed to extreme lengths and technological changes were astronomical. Fortunately, the bravery of the designers and engineers was rewarded and it became a huge success. If you are looking to replace the engine of MK3 that you own or drive then you have landed at the right place as Royal Rebuilds manage one of the largest stocks of the Range Rover engines in United Kingdom and can provide you new, used or reconditioned Range Rover MK3 engines at fantastic and unbeatable prices.

Range Rover Mk3; A Benchmark Vehicle

Range Rover MK3 was the third generation Range Rover and it really came off age as it became a benchmark for the luxury SUV vehicles. First ever Range Rover to break free from the old ladder frame chassis and adopt a modern monocoque shell and independent four-wheel air suspension was introduced for this generation. An independent design department was given free hand to let the ideas flow and boy have they produced a beauty. The looks of this vehicle were at ease anywhere. Whether you were driving down a red carpet or doing a school run with the kids or getting down and dirty in the mud strewn off road path, this vehicle was at home at each situation while keeping you absolutely at ease in the luxurious cabin.

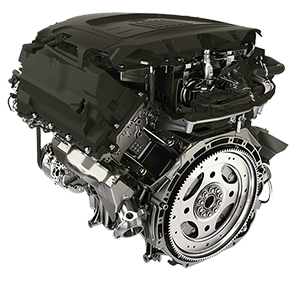

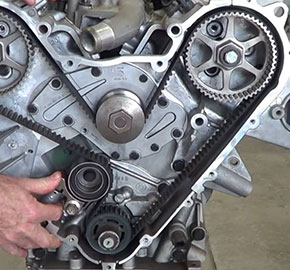

As far as the engines are concerned, Range Rover MK3 went through various engines and brands it started with BMW produced petrol and diesel engines and later was replaced with Jaguar V8 powerhouses. It did some experimentations with Ford diesel engines as well. In the same way the suspension was as diverse which included 5, 6 and 8 speed transmission.

Range Rover MK3 was not only a trail blazer in technical specifications, it also set trends in cabin luxury and comforts. It was easily one of the most luxurious and comfortable cabins laced with stylish details and technological achievements. Wood and leather were used in the whole cabin and hi-tech dials and lcd technology was standard in the cabin.

Range Rover MK3 was a game changer and saviour of the whole brand when it was in a nose dive. It defined the luxury SUV class and set the standards for other brands to follow. It also proved that with the right product and marketing strategy you can achieve unprecedented success.

MK3 Engine Replacement and Common Problems

Range Rover MK3 became a massive success for a reason. It was at ease on any surface you drive it on and the reliability was one of its strong selling points. Its engine was good enough to take on any load that you put on it but as with any other mechanical organization, engine is comprised of thousands of parts that work simultaneously to move the vehicle. With such huge sized engine and so much technology involved there is so much that can go wrong.

Range Rover MK3 are known for electrical faults, air suspension failure, oil leak from crankshaft etc. if your workshop suggests an engine replacement then it pays to know what choices do you have.

You can buy the engine from the dealership but its an expensive choice and could cost you an arm and leg. A money saving option could be to opt for used engine but you must ensure that you are getting a reliable engine otherwise you would end up spending more after the installation. Best option is usually considered to be the reconditioned MK3 engine that is basically an old engine that is taken apart in the facility and is remanufactured by replacing every suspected part. This engine is as good as a new engine when it comes to performance and reliability.

If we do not have your required engine in stock, not to worry, we would rebuild your existing faulty engine to the best of the standards.

Let the Royal Rebuilds Help You Choose

We have the most experienced mechanics who have decades of experience of replacing the engines and reconditioning them. We have a purpose-built facility that concentrate on Land Rover engine replacement and rebuild process. We use most up to date techniques to get the job done in most efficient and proper way possible. We guarantee exceptional results when it comes to replacements and rebuilds and total engine reconstruction from us can guarantee years of stress-free driving.

100% Customer Satisfaction With up to 60% Savings

We aim to provide 100% customer satisfaction when it comes to our loyal customers. We achieve this feat by offering written warranty on every engine being sold by us. Warranty period depends on the condition of the engine.

You can save up to 60% when you decide to buy a used or reconditioned engine from us rather than paying to the dealership for a crate engine. This can potentially save you up to 50% and there are further 10% savings available on festive season sales such as Christmas and other festive seasons. You can celebrate alongside us with a further discount if you keep your eyes peeled and visit the site on regular basis.

Let Us Pick and Drop Your Vehicle

Our lives are busy and most of the times we cannot spare time to collect the engines from us hence we offer fitting service where you can just bring your vehicle and get the engine replaced or you can contact us and we would collect your vehicle from where ever you want us from, bring the vehicle into our facility and get the engine replaced. We would do our routine testing to ensure the quality of the procedure is maintained and once we are satisfied with the results, we would return the vehicle back to the address that you provide us. This way you do not have to leave the safety of your home and we can complete the whole process without exposing you to any danger during the worst pandemic the world has ever seen.