Having your own engine reconditioned has several important advantages:

- Client maintains their original engine number so there is no need to contact DVLA to process administration changes on the vehicle logbook

- Modern vehicle engines have a large number of variations and specs, having your own engine avoids these compatibility issues

- Once the engine is stripped down and prepped for rebuilding, Royal Rebuilds experienced technicians diagnose the block, head and internals. This is a crucial part of the rebuild and in many occasions the cause of failure can be identified. Understanding the route cause can be very helpful for the client to minimise future risks.

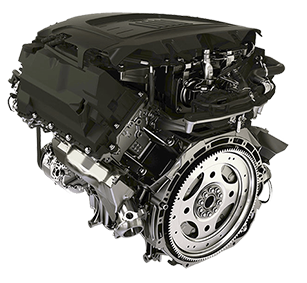

The Reconditioning Service We Offer

A full engine rebuild carried out by ourselves includes all the following components to be replaced on the engine block with brand new approval parts:

- Oil pump

- Piston rings

- Main ends and big end bearings

- Crankshaft

- Liner honed or re-bored

- Full gasket set

Also the Cylinder Head(s) will be reconditioned in house which includes:

- Pressure testing

- Valves and seats being refaced

- Brand-new valve stem Seals

- Head gasket(s)

- Camshafts

- Tappets/hydraulic lifters

- Cam-carrier

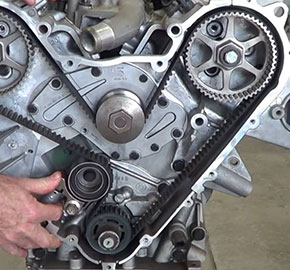

A new timing chain or timing belt will also be installed.