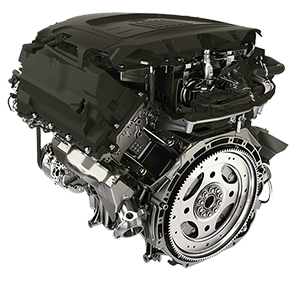

Range Rover engines are efficient and technologically advanced machines that produce brilliant power along with efficient and economical performance. Every engine can show problems after extensive use. If your mechanic has advised you to find a replacement engine for your Range Rover, then Royal Rebuilds can be a great help. We can help you find some great bargains in used or reconditioned Range Rover 3.0 replacement engines.

This engine is capable of churning out 254 bhp and can bolt from 0-62 mph in 8 seconds. It can reach the top speed of 130 mph and can give an average of 40.9 mpg, depending on the model and trim you use.

We assure you a price difference that is sure to save you up to 50% of the amount when compared to the price of a brand new engine from the dealership. You can also take advantage of our seasonal or festival offers, where we provide our loyal customers with up to 10% additional discount, which means you get up to 60% discount when you choose us. You get absolute satisfaction as you are offered a warranty by the sellers, depending on the condition and the price of the engine.

We also offer fitting service at affordable prices and can pick up and drop off your vehicle in case you do not have the time to drop the vehicle off yourself. Our services are second to none. Come and feel the difference that we make.

Frequently Asked Questions

1. What makes the 3.0 TDV6 diesel engine in Range Rover models so popular?

The 3.0 TDV6 is a refined V6 diesel engine that balances power and fuel efficiency for Range Rover Sport, Vogue and Discovery 4 owners. Its widespread use means parts, engine codes (such as 306DT and S-DV6), and technical support are easy to source for repairs, rebuilds or replacements.

2. How do I know my Range Rover 3.0 L diesel engine has suffered catastrophic engine failure?

Warning signs include low oil pressure, excessive smoke, knocking noises and limp-mode activation. If your vehicle suddenly stops or “suffers a catastrophic engine failure,” call our engine specialists immediately to avoid secondary damage to turbos, injectors and ancillary components.

3. Can you supply and fit a reconditioned Range Rover Sport engine?

Yes. We hold a large stock of used and reconditioned engines, and offer a complete engine supplied and fitted service for Land Rover Range Rover Sport 3.0 TDV6 and SDV6 models. This includes removal, installation, coding and road testing—backed by a written warranty.

4. What is the difference between a used engine and a reconditioned engine?

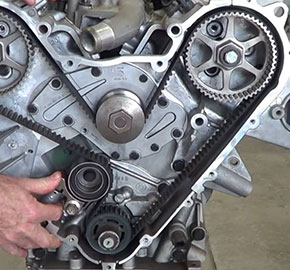

A used engine is removed from a donor vehicle with minimal refurbishment. A reconditioned engine (also called a rebuilt or remanufactured unit) goes through a full engine reconditioning process—strip-down, machining, new bearings, gaskets, oil pump, timing kit and extensive engine testing checks.

5. Do you rebuild the engine I already own or supply an exchange unit?

Both options are available. We can perform a full engine rebuild on your existing engine, or expedite the job by exchanging it for a pre-built bare engine or complete engine from our inventory.

6. How long does a Range Rover engine rebuild take?

Turnaround is typically 7-10 working days for a 3.0 TDV6 or 3.0L 306DT SDV6, depending on parts availability and machine-shop queues. An engine replacement with a ready-to-go unit can reduce downtime to 2-3 days.

7. Will a rebuilt engine improve reliability over my factory unit?

Yes. Our reconditioned Land Rover engines are built to tighter than OEM tolerances, eliminating original design weaknesses and restoring factory performance. Many customers remark that their Range Rover feels “like new” after the swap.

8. What warranty do you provide on reconditioned Land Rover and Range Rover engines?

All rebuilt engines come with a 12-month or 12,000-mile warranty (whichever occurs first) covering parts and labour when the engine is supplied and fitted by our team of Rover engine specialists.

9. Do you cover all Range Rover models and years?

We stock solutions for Range Rover Sport V6 diesel (2009-2023), Range Rover Vogue 3.0 L TDV6, Discovery Range Rover Sport 3.0 L 306DT, plus late-shape Land Rover Range Rover 3.0 SDV6 and 3.0L GEN-2 engines.

10. How can I confirm the correct engine code for my Range Rover?

Locate the code on the VIN plate or engravings on the block near the starter. Popular Rover engine codes include 306DT, 306D1, DT308 and DT306 SDV6 GEN2. Our team can decode your VIN if you’re unsure.

11. Is it cheaper to buy top quality 3.0 engines from us than from a main dealer?

Absolutely. Our replacement Land Rover engines are often 40–60% less than dealer price, without compromising quality. We also offer low-mileage used Range Rover Sport engines for sale if the budget is tight.

12. Do you test the engine before it leaves your workshop?

Every reconditioned and used engine undergoes hot-run dyno simulation, compression testing, oil-pressure verification and electronic balance checks to ensure it “fits and fires” the first time.

13. Can you arrange collection of my vehicle or engine?

Yes, we run a nationwide recovery and courier service. We’ll collect your vehicle or engine, carry out the work, and return your Range Rover fully tested—saving you time and stress.

14. Will upgrading to a new engine affect my insurance or road tax?

Replacing your diesel engine with a like-for-like 3.0 TDV6 will not usually change insurance or emission based road tax, but we recommend informing your insurer to update their records.

15. Can a reconditioned Range Rover Sport engine improve fuel economy?

A freshly rebuilt engine restores original compression and injector performance, often leading to noticeable MPG gains compared with a tired high-mileage unit.

16. What is included in the price of an engine replacement?

Our quotes cover the engine, labour, genuine or OEM gaskets, oils, filters, coolant, diagnostics, road test and VAT—no hidden extras. Ask for a free engine quote tailored to your VIN.

17. Do you carry out partial repairs like timing-chain kits or crankshaft replacements?

Yes. If your 3.0 L diesel suffers chain rattle, oil-pump failure or crankshaft snap, we can repair or rebuild only the affected section, though a full reconditioned engine is often more cost-effective.

18. What payment options are available for engine works?

We accept debit/credit cards, bank transfer and finance packages on reconditioned and used engines. Speak to our team for flexible and discounted plans.

19. How do I maintain my rebuilt Range Rover engine?

Follow Land Rover’s 12,000-mile/12-month service schedule, use 5W-30 ACEA C1-C2 oil, change filters regularly and avoid extended idling to maximise longevity.

20. Can you retrofit a newer 3.0 L SDV6 GEN-2 engine into an older Range Rover Sport?

Yes, provided ECU software and ancillary upgrades are completed. Our engineers will advise on compatibility, wiring and exhaust requirements before starting.

21. Do you sell engines for other Land Rover vehicles?

We cover Defender, Discovery 4, Discovery 5 and Rover vehicles fitted with the 2.7 TDV6, 3.0 SDV6, 4.4 TDV8 and 5.0 petrol units and many more.

22. What happens to my old engine after replacement?

Core engines are either recycled for parts or fully reconditioned and returned to stock, supporting a sustainable, circular supply chain.

23. Why choose Royal Rebuilds over generic engine suppliers?

We’re dedicated JLR vehicle engine specialists with decades of experience, factory grade machining, OE parts and transparent pricing, plus hundreds of 5-star reviews from Range Rover owners.

24. Can I buy an engine “cash & carry” without installation?

Certainly. We can supply a bare engine or turnkey complete engine palletised for shipping UK wide, with fitting instructions and tech support.

25. How quickly can I get my Range Rover Sport engine replaced if it just failed?

Contact us before noon, and—subject to stock—we can start same-day removal, ensuring that your Range Rover is back on the road within 48–72 hours with a fully tested, warrantied engine, but all these depend on the garage workload.

26. How many gears are in the automatic Range Rover 3.0 diesel?

- 2009-2011 3.0 TDV6 models use a 6-speed ZF 6HP26 automatic.

- From the 2012 model-year onward (TDV6/SDV6), the engine is paired with an 8-speed ZF 8HP70 automatic.

27. Is the 3.0-litre Range Rover diesel engine any good?

Yes—its twin-turbo design gives strong low-rev torque and better economy than the earlier 2.7 TDV6, and it’s widely used across Land Rover and Jaguar models. Regular oil changes are essential because neglected engines can suffer crankshaft or bearing failure—an issue specialist rebuilders like Royal Rebuilds fix.

28. What engine is in the 2013 TDV6 3.0 Range Rover?

It’s the Ford/PSA “Lion” all-aluminium 3.0 L V6 diesel (engine code 306DT, Jaguar-Land Rover code AJD-V6) with common-rail injection and twin turbochargers, rated at about 255 PS and 600 Nm.

29. Which engine is better: the 2.7 TDV6 or the 3.0 TDV6?

The 3.0 L is generally preferred, offering 20-35% more power and torque, twin turbos, and the option of an 8-speed gearbox, while maintaining similar fuel consumption. The older 2.7 L is simpler and slightly cheaper to maintain, but lacks the performance and efficiency gains.

30. Who makes the 2013 TDV6 3.0 Range Rover engine?

The engine was co-developed by Ford of Europe and PSA Peugeot-Citroën and assembled for Land Rover at Ford’s Dagenham Diesel Centre in the UK.