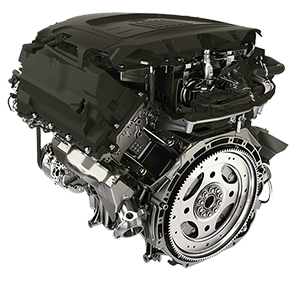

Range Rovers come with some of the most innovative and technologically advanced engine technology. This makes the engines extremely fuel-efficient and potent. However, it’s the nature of a machine to show signs of wear and tear with time. If your Range Rover is also facing problems with its engine then Royal Rebuilds could be a great help. We can help you acquire reliable and working used and reconditioned Range Rover 2.2 engines at affordable prices.

This 2.2 Range Rover engine is capable of producing 190bhp and speeds up from 0-62 mph in a mere 9.5 seconds with top speed limited at 124 mph. the economy of this car is approximately 49 mpg depending on which vehicle and trim we look at.

It is beneficial to buy a used or reconditioned engine for your Range Rover instead of forking out too much money in the dealership. You can save up to half the amount when compared to the new engine price. We ask our sellers to provide a written warranty with each engine sold. We urge you to come and experience our services to know the difference we make.