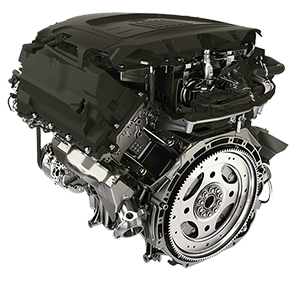

Range Rover is a brand synonymous with quality, predictability, and power. They are known to make vehicles that are capable of performing on any terrain. Part of this is because of their superior designs and suspension and a big chunk of performance comes with the help of powerful engines. If you ever get to the point where an engine replacement for your Range Rover is necessary, then you can trust upon Royal Rebuilds to help you find and purchase the working and dependable replacement Range Rover 4.4 engines at incredibly low prices.

This dynamic powerhouse can produce 296 bhp and can reach 62 mph from a standstill in mere 8.9 seconds. It has a top speed of 130 mph and gives fuel consumption of 19 mpg. Power is transmitted to the tarmac through all-wheel drive transmission with a 6-speed sequential gearbox.

We assure you that if you decide to buy the engine from us, you can save up to 60% when compared to the crate engine price from the dealership. We also provide a written warranty depending on the condition and price of the engine and offer a fitting service in the workshop as well.