Range Rover introduced vehicles that are capable of performing faultlessly at any sort of surface. Be it tarmac, mud, sand, or ice. Range Rover can be trusted to go anywhere. This vehicle owes much to its brilliant and powerful engines for giving it such invincibility over difficult terrains. Although those engines are dependable and robust, sometimes you are required to replace the engines to keep your vehicle working. Royal Rebuilds is your one-stop shop where you can find and buy Range Rover engine and get it fitted as well at bargain prices.

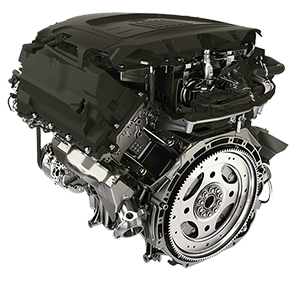

Range Rover 5.0 engines is a beast of an engine that can churn out 503 bhp at boast the acceleration figures of 6.2 seconds for 0-62 mph. it can achieve a top speed of 140 mph which is amazing for such a large engine and vehicle. It does all that while offering a decent fuel average of 19 mpg and is amazing in terms of raw power.

Our experienced and talented technicians can provide fitting service at affordable prices. We also offer to pick and drop service which means we pick your vehicle from anywhere in the United Kingdom, fix it and bring it back to your doorstep. We look forward to hearing from you.