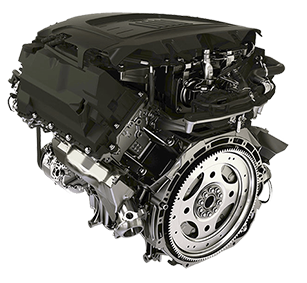

While buying a replacement engine may be safer from the dealership, it is also expensive. You are better off replacing the engine with a used or reconditioned engine. Royal Rebuilds stock and sell working and tested used and reconditioned Land Rover 2.7 engines at affordable prices.

This engine came into being after the Ford takeover of Land Rover brand. BMW engines were not a viable option anymore and Land Rover demanded an engine that was capable of fulfilling the demands of Land Rover vehicles. If you are looking to replace the engine of your Land Rover then Royal Rebuilds could be a great help to you as we deal in perfectly working used and reconditioned Land Rover 2.7 engines.

This TDV6 turbo charged diesel engine can produce a maximum of 187 hp and can accelerate from 0-60 in 11.5 seconds with a maximum top speed of 112 mph. its fuel efficient as well as it can provide 30 mpg average.

Best Place for Land Rover Engines

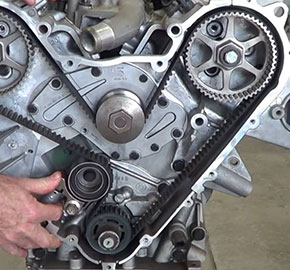

All you need to do is take an appointment and bring your vehicle to our facility. Our experts can suggest the right replacement engine for your Land Rover and take care of the whole process themselves. If for some reason we do not have the required engine available then we promise to rebuild your existing engine to such standards that it would be as good as a new engine.

We offer up to 60% savings when you decide to buy from us instead of forking out at the dealership. We also offer written warranty with every engine that we sell and can arrange the pick and drop delivery at minimal prices. Take an appointment and let us show you the difference that we can make with our services.